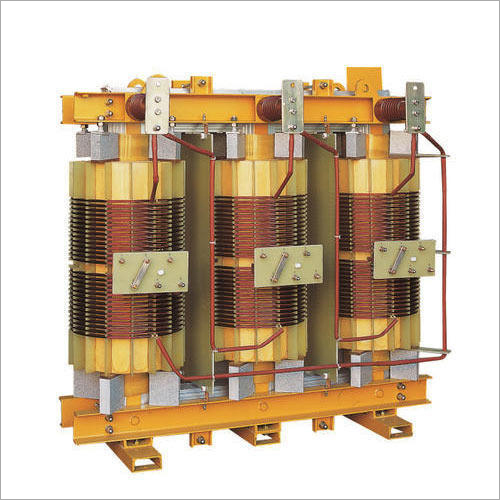

Dry Type Distribution Transformer

Dry Type Distribution Transformer Specification

- Low Voltage

- 415 V / 690 V

- Load Loss

- As per IS/IEC Standard

- Operating Temperature

- Up to 120C

- Capacity

- 100 kVA - 2500 kVA

- Rated Voltage

- 11 kV / 33 kV

- Voltage Booster Type

- Step Down / Step Up

- Coil Material

- Copper / Aluminum

- Cooling Type

- AN (Air Natural) / AF (Air Forced)

- High Voltage

- 11 kV / 33 kV

- Dimension (L*W*H)

- 1400 x 950 x 1600 mm

- Product Type

- Dry Type Distribution Transformer

- Material

- Copper, Epoxy Resin, Steel

- Output

- Custom as per requirement

- Frequency (MHz)

- 50-60 Hz

- Efficiency

- 98% Approx.

- Phase

- Three Phase

- Usage

- Electrical Distribution

- Coil Structure

- Toroidal & Layer Winding

- Coil Number

- 2-3

- Power Scope

- Up to 2500 kVA

- Weight

- 1200 kg - 3500 kg (Depending on Rating)

- Noise Level

- Below 60 dB

- Insulation Class

- F/H Class

- Winding Type

- Vacuum Pressure Impregnated (VPI)

- Fire Safety

- Self-extinguishing, non-flammable

- Standards Compliance

- IS 11171, IEC 60076-11

- Dielectric Strength

- Up to 55 kV

- Enclosure Protection

- IP23/IP 31/IP 41

- Temperature Rise

- As per IEC/IS standards

- Tap Changer

- Off-circuit tap links / On-load tap changer (optional)

- Impedance Voltage

- 4% to 6%

Dry Type Distribution Transformer Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- Chhattisgarh, Nagaland, Arunachal Pradesh, Jharkhand, Andaman and Nicobar Islands, Tripura, Bihar, Mizoram, Sikkim, West Bengal, Odisha, Assam, Meghalaya, Manipur

About Dry Type Distribution Transformer

Reliable Insulation and Safety

The transformer employs F/H class insulation and self-extinguishing, non-flammable epoxy resin, enhancing safety by resisting fire and heat. Dielectric strength up to 55 kV and strict adherence to IS and IEC standards ensure dependable operation, even in demanding conditions. This product is meticulously crafted for durability and long-term stability in power distribution applications.

Flexible Design for Various Applications

Manufactured in multiple ratings from 100 kVA to 2500 kVA, this transformer supports custom output configurations, various winding types (toroidal and layer winding), and optional tap changers. Its versatility suits numerous environmentsfrom commercial buildings to industrial facilitiesaddressing a broad scope of electrical distribution challenges. The transformers are available with copper or aluminum windings, matching diverse project specifications.

Efficient Operation and Low Maintenance

Engineered for energy efficiency (approximately 98%) and low noise (below 60 dB), the transformer promises silent and cost-effective operation. With a cooling system supporting both air natural (AN) and air forced (AF) modes, it remains reliable even under heavy loads. Minimal maintenance is required due to robust VPI winding and stringent manufacturing standards.

FAQs of Dry Type Distribution Transformer:

Q: How is the dry type distribution transformer installed and maintained?

A: Installation requires placement in a well-ventilated indoor or outdoor area, following local electrical codes. The robust IP23/IP31/IP41 enclosures minimize environmental impact. Routine maintenance is simpleprimarily visual inspection and cleaning, as the vacuum pressure impregnated windings and solid insulation limit wear. No oil checks or refills are necessary.Q: What are the main advantages of using an insulation class F/H dry type transformer?

A: Insulation class F/H provides enhanced thermal endurance and fire safety. The self-extinguishing, non-flammable epoxy resin reduces fire risk, making it ideal for locations with stringent safety requirements, such as commercial complexes, hospitals, or data centers.Q: When should a tap changer be chosen for use with this transformer?

A: A tap changer is recommended when voltage regulation flexibility is needed. Off-circuit tap links allow adjustment during maintenance shutdowns, while the optional on-load tap changer enables voltage control during operation without interrupting the supply. Choose according to application requirements for voltage consistency.Q: Where can this transformer be used effectively?

A: This transformer suits a wide range of applications, including factories, commercial buildings, institutions, and public infrastructure projects. Its enclosure options and fire-safe design ensure suitability for both indoor and outdoor installations, meeting the demands of diverse electrical distribution systems.Q: What materials and winding techniques are used in construction?

A: The transformer utilizes high-conductivity copper or aluminum windings, shaped using toroidal or layer winding structures. The windings are vacuum pressure impregnated (VPI), offering superior moisture protection and mechanical strength. An epoxy resin coating further enhances durability and electrical insulation.Q: How does the transformer ensure energy efficiency and low noise levels?

A: Precision engineering enables impressive efficiency (about 98%). The optimized core design and winding configuration reduce load losses, while careful mechanical construction and insulation techniques limit noise emission to below 60 dB, supporting quiet operation in sensitive environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dry Type Transformer Category

Iron Core Dry Type Transformer

Price 40000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Highgrade Silicon Steel Laminations, Copper or Aluminum Windings

Product Type : Other, Iron Core Dry Type Transformer

Usage : Power Distribution, Industrial, Commercial, Utility Applications

Phase : Three Phase

VPI Dry Type Transformer

Price 1100000 INR

Minimum Order Quantity : 1 Unit

Material : Copper/Aluminum with HighGrade Insulating Resin

Product Type : Other, VPI Dry Type Transformer

Usage : Industrial and Commercial Power Distribution

Phase : Three Phase

Three Phase Dry Type Transformer

Price 650000 INR

Minimum Order Quantity : 1 Unit

Material : Copper/Aluminum windings with highgrade laminated core

Product Type : Dry Type Transformer

Usage : Industrial electrical power distribution and isolation

Phase : Three Phase

Cast Resin Dry Type Transformer

Price 300000 INR

Minimum Order Quantity : 1 Piece

Material : Copper

Product Type : Dry Type Transformer

Usage : Resdential ,Hospital

Phase : Three Phase

|

ARUN ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry